-

Sublimation Inkjet Printer

-

Sublimation Textile Printer

-

Large Format Eco Solvent Printer

-

Digital Inkjet Printing Machine

-

Digital Printing Plotter

-

UV Inkjet Printer

-

Transfer Paper Printing Machine

-

Epson Wide Format Inkjet Printer

-

Advertising Printing Machine

-

Commercial Poster Printer Machine

-

Sublimation Fabric Printing Machine

-

Fedar Sublimation Printer

-

Skycolor Inkjet Printer

-

Storm Jet Printer

2.6m Roll To Roll Transfer Paper Printing Machine With I3200A1 Heads

| Printhead Type | Epson I3200-A1 | Quantity | 8 Pcs |

|---|---|---|---|

| Ink Color | CMYK | Ink Type | Dye Sublimation Ink,Pigment Ink |

| Printing Width | 2600mm | Printing Height | 2-5mm |

| Computer System | WIN7 64bit/WIN10 64bit | Media | Transfer Paper ,Poster Paper |

| RIP Software | Maintop, Photoprint,Neostampa,Onyx,etc. | Warranty | 1 Year |

| Resolution | 3200dpi | ||

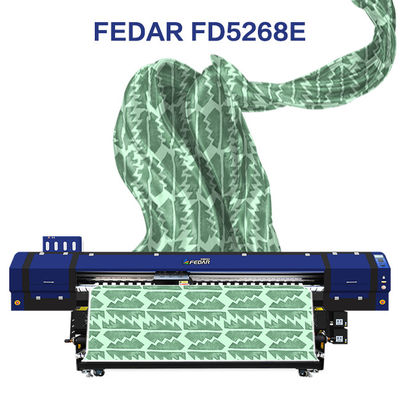

| High Light | FD5268E,2.6m Transfer Paper Printing Machine,Pigment Ink Transfer Paper Printing Machine |

||

Fedar 2.6m Roll To Roll Transfer Paper Digital Fabric Printing Machine With I3200A1 Heads

Our sublimation printer is used to make textile products, such as blanket, polyester dress, plush toys and so on.

It prints on sublimation papers first, then heat transfer the pattern to the fabric you want. Automatic printing and

dye sublimation ink make the pattern colors bright, strong and fantastic.

How Does Sublimation Printer Work?

* So how does sublimation printing work? After you have chosen your design, you should use a sublimation printer

to print it out onto the special paper. The design is then printed onto the fabric, by either using a heat press or

(if you are doing it at home) by applying pressure and putting it into the oven.

* You will have to use a transfer paper (usually sublimation paper) so that the design transfers onto the fabric.

Bringing the ink and the fabric together, the ink is embedded and therefore will remain more vibrant for longer

(in comparison to other printing processes). The heat in the press or the oven opens the fabric’s pores up, whilst

the pressure that’s put onto the fabric cools the ink down – turning it into a solid form. The press can then be

released and the paper gently taken off of the shirt or mug (or whatever object that you have used).

![]()

Fedar 2.6m Roll To Roll Transfer Paper Digital Fabric Printing Machine Parameter

| Printer Model | FD5268E | |

| Printhead | Type | EPSON I3200-A1 |

| Nozzle Qty | 8pcs printheads | |

| Height to Platform | 2-5mm | |

| Printing Speed | 1pass 350sqm/h | |

| 2pass 160sqm/h | ||

| Ink | Color | C M Y K |

| Type | Dye Sublimation | |

| supply method | Siphoning | |

| Max Printing Width | 2600mm | |

| Printing Media | Transfer Paper | |

| Media Transfer Method | Dual-drive tension take-up system,Auto air shaft feeding system | |

| Drying Method | External,Intelligent and air-heat Integrated drying system | |

| Moisture Mode | Fully sealed auto moisturing and cleaning | |

| RIP Software | Maintop6.0,Photoprint,Onyx,Wasatch and NeoStampa and etc. | |

| Image Format | JPG,TIF,PDF,BMP and etc. | |

| Computer | System | WIN7 64bit/WIN10 64bit |

| Hardware | Hard disk:500G (system disk more than 100G) GPU:ATI Discrete CD-ROM:DVD ROM Memory:4G or more CPU:Intel i5/i7 processor |

|

| Transmit Port | Gigabit LAN | |

| Work Environment | Temperature 20-35 centi degree; Humidity 35-65% | |

| Power | Input Voltage | 210-230VAC 50/60HZ 16A |

| Printing system | 1200W | |

| Drying system | Max power 3600W | |

| Dimension | Printer Dimension | 3790*880*1640mm |

| Packing Dimension | 3940*1185*1805mm | |

Fedar Transfer Paper Digital Fabric Printing Machine Feature

* 8 Epson I3200-A1 printhead,1 pass speed can reach up to 350㎡/h.

* Adopt two-level ink supply system to ensure continuous printing for a long time.

* Reduces the tediousness of frequently checking the remaining amount of ink, and at the same time reminds

to add ink in time.

* Convenient and fast, the printing media is quickly stored, equipped with automatic paper measurement and

anti-rubbing function.

* The fully-closed capping station with automatic lifting, tighter sealing and long-term moisturizing. Automatic

cleaning settings make printing cleaning simpler.

* Unique two-dimension intelligent foggy and wave-foggy function, and VSDT variable droplet technology,

improve printing quality obviously.

Fedar Roll To Roll Transfer Paper Digital Fabric Printer Feature

![]()

1.Specially Designed Car

The position of the print head can be adjusted according to different printing medias, and anti-collision devices

at both ends.

2.Intelligent Air-heat Dryer

The intelligent drying system is synchronized with printing.The temperature can be adjusted in real time

during the printing process.

3.Pinch Roller

US fluororubber pressure roller prevents static electricity.The unique lifting device can respond to the

phenomenon of partial paper bulging during the printing process.

4.High Precision Platform

The printing platform is controlled within ±7.5 wires and the surface hard oxidation treatment, no deformation for

a long time.

5.Germany IGUS Ink Chain

Imported Germany IGUS ink chain,high quality, to ensure the good completion of printing work.

Dye Sublimation Printing For Businesses: What Product Can You Print On?

Rigid Substrates – Polymer treated objects that include non-fabric items like glass, plastic, fiberglass, and aluminum.

These are products that aren’t bendable like fabrics.

Blank Rigid Products – Many of these materials are available to buy in bulk at wholesale prices, like custom mouse

pads,cell phone cases, and drinkware. They are sometimes referred to as “blanks”, which are products without any

designs or printing included so that personalization can be added.

Signage – Perfect for “click to print” e-commerce businesses. Easily print on vinyl to create retractable banners and

other trade show displays. When seeing signs hanging in front of shops or buildings, there’s a good chance that

sublimation was used.

Polyester Fabrics – One of the most popular items to dye sublimate. They are divided into two types:

(1)Knit: Polyester products that hang & flow in their natural environment, like apparel, flags, banners, and custom printed

table covers.

(2)Woven: More durable products such as custom tote bags fabric backdrops, and custom tents.

Home Decor – The dye-sub process is often used by businesses that sell to interior designers. Decor items like

ceramic floor tiles are a popular choice for bathrooms, kitchens, restaurants, & more.

Photograph Printing – Arguably the best way to produce the highest-quality photographic images on canvas, magnets,

and apparel.

2.6m Fedar Sublimation Textile Printer Application

![]()