-

Sublimation Inkjet Printer

-

Sublimation Textile Printer

-

Large Format Eco Solvent Printer

-

Digital Inkjet Printing Machine

-

Digital Printing Plotter

-

UV Inkjet Printer

-

Transfer Paper Printing Machine

-

Epson Wide Format Inkjet Printer

-

Advertising Printing Machine

-

Commercial Poster Printer Machine

-

Sublimation Fabric Printing Machine

-

Fedar Sublimation Printer

-

Skycolor Inkjet Printer

-

Storm Jet Printer

1500W 8 Heads 1.9m CMYK Fedar Sublimation Printer

| Print Head | I3200-A1 | Printhead Quantity | 8 |

|---|---|---|---|

| Maximum Media Width | 1900mm | Ink Color | CMYK |

| Ink Type | Sublimation Ink,Water Based Pigment Ink | RIP Software | NeoStanpa,Ergosoft, Onyx,Photoprint,Maintop |

| Motor | Leadshine | Computer System | Win7,Win8,Win10 |

| Warranty | 12 Months | ||

| High Light | CMYK Fedar Sublimation Printer,1.9m Fedar Sublimation Printer,8 Heads Fedar Sublimation Printer |

||

1.9m Fedar Sublimation Inkjet Printer With High Effiency Production

FEATURE

* High Resolution Printhead:

8 Epson I3200-A1 printhead,2 pass speed can reach up to 260 sqm/h.

* Two-level Ink Supply System:

Adopt two-level ink supply system to ensure continuous printing for a long time.

* Intelligent Ink Starving Alarm:

Reduces the tediousness of frequently checking the remaining amount of ink, and at the same time reminds to add ink in time.

* Stable Media Feeding and Take-up System:

Convenient and fast, the printing media is quickly stored, equipped with automatic paper measurement and anti-rubbing function.

* Advanced Capping Station:

Equipped with advanced intelligent auto printhead cleaning and moisturizing device,which can pump ink well and keep the

ink flow fluently.

* Foggy & VSDT Printing:

Unique two-dimension intelligent foggy and wave-foggy function, and VSDT variable droplet technology,improve printing

quality obviously.

DETAIL

![]()

Maintenance Capping Station:

Motor-drive capping maintenance station replacing traditional cracked capping,improve head life.

Pinch Rollers:

Adopt multi-row pinch roller made of American rubber eliminating statics,high printing quality.

![]()

Ink Tank:

Bulk ink supply system,transparent ink tank design which is convenient for operator to observe ink allowance

in time.

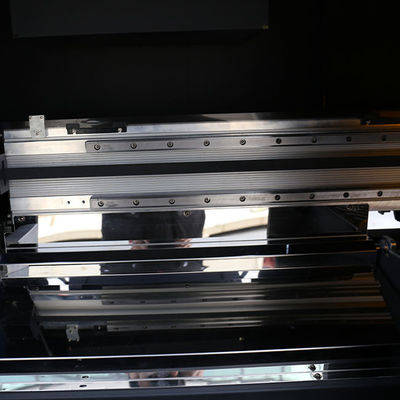

Dual THK Guide Rail:

Imported Japan double THK guide rails makes carriage movement more smooth and more accuracy.

![]()

Carriage:

The position of the print head can be adjusted according to different printing medias, and anti-collision

devices at both ends.

Platform:

Finishing aluminum platform has a longer service life.

APPLICATION

Dye Sublimation Textile Printer can support print different gsm transfer paper, 45 to 100 gsm, and transfer

on polyester(contton<30%) Sportswear, curtain, dress, shoes, carpet, silk, bed sheet, etc.

![]()

SERVICE

Pre-sale service

1. 7day*24hours Hot-line & Email service for inquiry.

2. Confirm the price, lead time, artwork, payment term etc.

3. Sales send the Proforma Invoice for you to confirm.

4. Customer make the payment for deposit and send us Bank Receipt.

In-sale service

1. Material and accessories carefully check upon arrival.

2. Make the sample according to customer require, send photos or samples to get customer approval.

3. After approval, we'll timely update you the production and delivery time.

4. Send photos to show the production status.

5. Confirm the exact delivery time again.

6. Clients make payment for balance then freedom ship the goods.

7. Inform the tracking number and check the status for you.

After-sale service

1. Solve any problem you may have and help you improve the relationship with your customers.

2. Timely update price change and new products' message.