-

Sublimation Inkjet Printer

-

Sublimation Textile Printer

-

Large Format Eco Solvent Printer

-

Digital Inkjet Printing Machine

-

Digital Printing Plotter

-

UV Inkjet Printer

-

Transfer Paper Printing Machine

-

Epson Wide Format Inkjet Printer

-

Advertising Printing Machine

-

Commercial Poster Printer Machine

-

Sublimation Fabric Printing Machine

-

Fedar Sublimation Printer

-

Skycolor Inkjet Printer

-

Storm Jet Printer

CMYK 3 Head Fedar TC1943 Sublimation Textile Printer

| Usage | Transfer Paper | Head | EPS On I3200-A1 |

|---|---|---|---|

| Head Quantity | 3 | RIP Software | Neostampa, Photoprint |

| Print Width | 1900mm | Color | CMYK |

| Ink Type | Sublimation Ink, Water Based Pigment Ink | Warranty | 1 Year |

| Motor | Leadshine | ||

| High Light | Fedar TC1943 Sublimation Textile Printer,3 Head Sublimation Textile Printer,CMYK Sublimation Textile Printer |

||

Fedar TC1943 New And Advanced Digital Sublimation Fabric Printing Machine

Our sublimation printer is used to make textile products, such as blanket, polyester dress, plush toys and so on. It prints

on sublimation papers first, then heat transfer the pattern to the fabric you want. Automatic printing and dye sublimation ink

make the pattern colors bright, strong and fantastic.

Printhead Technology & Advantages

A.Printing width of EPS I3200-A1 head is 1.3 inch,about 30% wider than F1440-A1, 3200 nozzles(400*8lines),which has much

higher speed and resolution than F1440-A1.

B.EPS I3200-A1 printhead adopts TFP technology,with the smallest droplet 2.5PL,variable dots technology,can ensure perfect

and high resolution printing performance.

C.Low cost,each head is about 300-350USD,which helps client reduce investment cost to get more benefit!

D.Compared with Epson 5113 heads,the ink column makes hoses connection much easier and more simple,very convenient

maintenance.

New And Advanced Digital Sublimation Fabric Printer Parameters

Fedar TC1943 Digital Sublimation Fabric Printing Machine Feature

* THK Guide Rail:

Adopt Japan THK silent linear guide makes the carriage movement is more stable and the life is longer.

* Printhead:

EPS on I3200-A1 printhead adopts TFP technology,with the smallest droplet 2.5PL,variable dots technology,can ensure perfect

and high resolution printing performance.

* Platform:

Platform adopts 8mm aluminimum alloy,which can reduce the shape variables during transportation.

* Pinch Roller:

Specially designed pinch roller to ensure more accurate media movement.

* Leadshine Motor:

Leashine server motor driver,high resolution and stable.

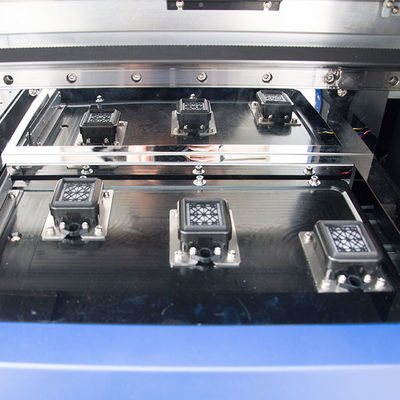

Fedar Advanced Digital Sublimation Fabric Printing Machiner Deatil

![]()

1. Capping Maintenance

Printer adopt automatic cleaning and capping system which makes the operation and maintenance more

convenient.

2. Ink Tank

Adopt sub-tank ink supply system,make sure long time printing,more stable.

3. Carriage

The carriage equipped with anti-collision system can ensure the normal operation of the carriage.

4. Pinch Roller

Multi-row independent pinch rollers,which can be lifted seperately,ensure the media moving without wrinkle.

5.Drying System

Intelligent infrared heating & blowing extenal dryer accelebrates media drying speed,meanwhile heating and

printing can be synchronous to reduce the energy waste.

6.Guide Rail

Imported Japan THK silent guide rail,high resolution and excellent stability.

Why Eps on I3200-A1 head is widely used on sublimation field rather than F1440-A1?

1. Epson I3200-A1 head has 8*400=3200 nozzles / Epson F1440-A1 head has 8*180=1440 nozzles

More nozzles mean higher speed.

2. Printhead Ignition frequency: Epson I3200-A1--16.7K, Ep son F1440-A1---14.4K

Ignition frequency means the dots sprayed from nozzles on media at unit interval time. Higher ignition

frequency means faster speed.

3. Printhead nozzle dot: Epson I3200-A1---3.8pl-7pl-12pl, Epson F1440-A1---3.5pl-6pl-12pl

Smaller dots can accumulate and form more different sizes of droplets and generate more gradation.

4. Electronic board.

Electronic boards greatly determine the printing speed and printer stability, AT boards are used on Fedar

printer for many years, excellent stability has won the favor from global customers.

Fedar TC1943 Digital Sublimation Fabric Priner Application

With help of heat transfer machine,printed images can be transferred to many different non-elastic material,

such as polyester and flag banner. No limit on the patterns makes it a good choice in decoration, garment and

advertising field.

![]()