-

Sublimation Inkjet Printer

-

Sublimation Textile Printer

-

Large Format Eco Solvent Printer

-

Digital Inkjet Printing Machine

-

Digital Printing Plotter

-

UV Inkjet Printer

-

Transfer Paper Printing Machine

-

Epson Wide Format Inkjet Printer

-

Advertising Printing Machine

-

Commercial Poster Printer Machine

-

Sublimation Fabric Printing Machine

-

Fedar Sublimation Printer

-

Skycolor Inkjet Printer

-

Storm Jet Printer

3pcs 4720 Heads 1.9m Dye Sublimation Fabric Printing Machine

| Usage | Transfer Paper | Ink | Sublimation Ink |

|---|---|---|---|

| Application Area | Sportswear, Dress, Cloth, Curtain, Etc. | Head | 4720 |

| Head Quantity | 3 | Print Width | 1900mm |

| RIP Software | Neostampa, Photoprint | Control Board | Hoson |

| Computer | Win7/win8/win10 | Color | CMYK |

| High Light | 1.9m Dye Sublimation Fabric Printing Machine,3pcs 4720 Sublimation Fabric Printing Machine,4720 dye sublimation printer |

||

Textile Market Dye Sublimation Fabric Printing Machine With 3pcs 4720 Heads

3pcs Heads Sublimation Model Parameters

| AL193 Sublimation Printer | ||||

| Printhead | Epson4720 | Nozzle Quantity | 3200 | |

| Printhead Quantity | 3 | Print Width | 1900mm | |

| Ink Color | CMYK | Print Height | 2-5mm | |

| Resolution | 360*1200/360*1800/ 720*1200/720*1800(DPI) |

Media Transfer | Auto Tension Taking-Up Meida Device | |

| Speed *Tested on linear printing without feather function |

2pass | 120㎡/h | Drying Method | Extra Dryer Device |

| 3pass | 85㎡/h | Ink Supply Method | Siphon Positive Pressure Ink Supply | |

| 4pass | 65㎡/h | Head Moisture Method |

Auto Head Cleaning and Moisturize | |

| 6pass | 45㎡/h | Print Media | Transfer Paper | |

| Ink Type | Sublimation Ink, Water based Pigment Ink |

Transmission Interface |

Gigabit LAN | |

| Computer System | Win7, Win8, Win10(Professional) | File Forms | TIFF, JPG, EPS, PDF, etc. | |

| Operate Environment | Temp.:15℃-30℃, Humidity: 35℃-65℃ | RIP Software | NeoStanpa,Ergosoft, Onyx,Photoprint,Maintop |

|

| Package Size | 3250*960*1170mm | Power Supply | 210-230V, 50/60HZ, 16A Print Power: 1000W Dryer Power: Max.3500W |

|

| Computer Configuration | Hard Disk: NTFS, C Disk Space: More than 100G, HARD Disk:WG500G GPU: ATI Discrete GPU, Memory: 4G, CPU: Inte I5/I7, G-Ethernet |

|||

| Standard Configuration | Ink Level Alarm System | |||

Al193 Detail Shows

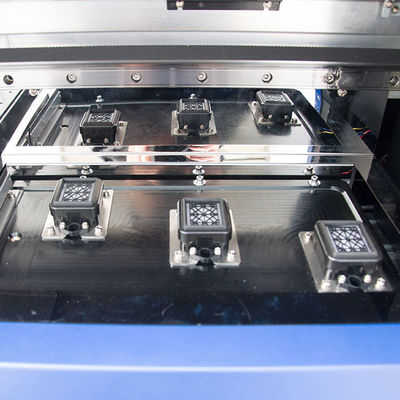

1. Anti-collision Car for Fedar AL193 Sublimation Printer with Epson 4720 head (EPS3200 head Printer)

The distance between printhead and printing platform can be adjusted freely according to different printing consumables. Anti-collision devices are added at both ends to provide more comprehensive safety protection for printheads.

2. Advanced Capping Station: Fedar AL193 Sublimation Printer with Epson 4720 head (EPS3200 head Printer)

Equipped with advanced intelligent printhead cleaning and moisturizing device, it provides safe and convenient printhead cleaning and maintenance functions,which can also pump ink well and keep the ink flow fluently.

Operation and maintenance is more convenient.

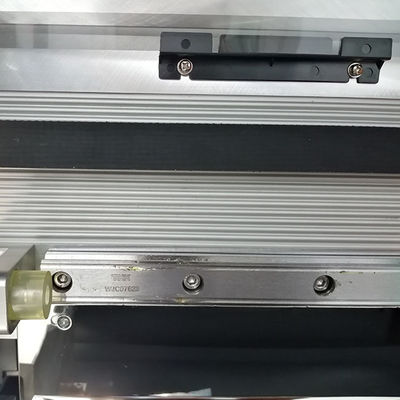

3. High Quality THK mute guide rail and slider for Fedar AL193 Sublimation Printer with Epson 4720 head (EPS3200 head Printer)

More stable running,longer working life,lower noise.higher resolution,and fewer errors in length.

4. Leadshine Motor for Fedar AL193 Sublimation Printer with Epson 4720 head (EPS3200 head Printer)

Both the servo and stepping systems are driven by high-quality brushless integrated Leadshine motor with high-precision linear decoding, smaller error,higher precision and more stable operation.

5. Large Capacity & Two Stage Ink Reservoirs for Fedar AL193 Sublimation Printer with Epson 4720 head (EPS3200 head Printer)

Four units of 3L super large capacity ink reservoirs provide ink independently and continuously, which guarantees the long-term continuity of ink output,and keep wide format high-speed printing wonderfully.

Two stage ink supply system provides more guarantee for non-stop ink output.

![]()

![]()

Application for AL193

![]()

Service

Pre-sale service

1. 7day*24hours Hot-line & Email service for inquiry.

2. Confirm the price, lead time, artwork, payment term etc.

3. Sales send the Proforma Invoice for you to confirm.

4. Customer make the payment for deposit and send us Bank Receipt.

In-sale service

1. Material and accessories carefully check upon arrival.

2. Make the sample according to customer require, send photos or samples to get customer approval.

3. After approval, we'll timely update you the production and delivery time.

4. Send photos to show the production status.

5. Confirm the exact delivery time again.

6. Clients make payment for balance then freedom ship the goods.

7. Inform the tracking number and check the status for you.

After-sale service

1. Solve any problem you may have and help you improve the relationship with your customers.

2. Timely update price change and new products' message.