-

Sublimation Inkjet Printer

-

Sublimation Textile Printer

-

Large Format Eco Solvent Printer

-

Digital Inkjet Printing Machine

-

Digital Printing Plotter

-

UV Inkjet Printer

-

Transfer Paper Printing Machine

-

Epson Wide Format Inkjet Printer

-

Advertising Printing Machine

-

Commercial Poster Printer Machine

-

Sublimation Fabric Printing Machine

-

Fedar Sublimation Printer

-

Skycolor Inkjet Printer

-

Storm Jet Printer

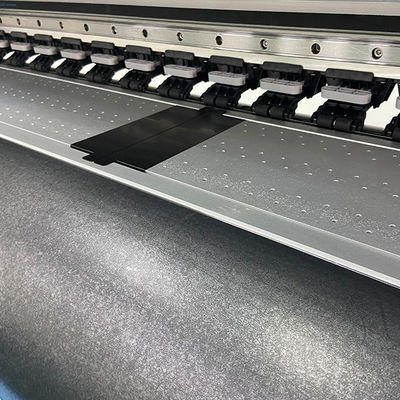

Stormjet Textile Printing Machine 4 Heads Eco Solvent Inkjet Printer

| Head Type | F1440-A1/ I3200-A1/I3200-E1 | Ink Type | Water-based Ink Or Eco Solvent Ink |

|---|---|---|---|

| RIP Software | Maintop, Photoprint, Onyx | Package | Export Crate |

| High Light | Stormjet Textile Printing Machine,4 Heads Eco Solvent Inkjet Printer,1800mm Eco Solvent Inkjet Printer |

||

Advantages Of EPS3200 Head:

1. With 3200 nozzles(8*400), printing speed can reach 80Sqm/H with 2 heads, it’s with higher speed and higher

resolution than Dx5.

2. EPS3200 adopts TFP technology, smallest droplet is 2.5pl, variable dots technology, can ensure perfect high

resolution printing effect.

3. EPS3200 head is available for water-based ink, eco solvent ink, solvent ink, sublimation ink, UV ink, pigment

ink, it’s widely used in printing industry.

4. EPS3200 is much cheaper than Dx5. Head replacement cost will be cheaper.

5. We are the only supplier of this EPS3200 head's decode board in China, that means all factories must take

decode board from us.

New And Advanced Stormjet Textile Printing Machine Parameter

Stormjet Textile Printing Machine Feature

* Japan THK linear guide rail makes carriage movement smooth and lower noise.

* Intelligent infrared heating & blowing external dryer accelebrates media drying speed, meanwhile heating and

printing can be synchronous to reduce the energy waste.

* Head maintenance can be done from printer directly without connecting computer.

* Support calibration settings parameter export and import, more convinient on operation and service.

Stormjet Printing Machine Detail

![]()

1.Capping Station:

Patented designed maintenance capping station .It's lifted up and down via column driven by motor in the middle,

which greatly maintain the balance of capping comparing the traditional gear dive.

2.Ink Tank:

Reduces the tediousness of frequently checking the remianing amout of ink and at the same time reminds to

add ink in time.

3.Carriage:

Adjustable carriage frame,applicate for different thickness of media.Max printing height is 5mm.

4.Pinch Roller:

Special designed pinch roller,each one can be lifted seperately to eliminate the wrinkle caused by media.

5.Drying System:

Three ways heating system , front ,middle,back individual,improve the printing quality.

6.Guide Rail:

Adopt Japan THK mute linear guide rail,the movement is more stable and the life is longer.

Stormjet F1-4 Printer Application

![]()