-

Sublimation Inkjet Printer

-

Sublimation Textile Printer

-

Large Format Eco Solvent Printer

-

Digital Inkjet Printing Machine

-

Digital Printing Plotter

-

UV Inkjet Printer

-

Transfer Paper Printing Machine

-

Epson Wide Format Inkjet Printer

-

Advertising Printing Machine

-

Commercial Poster Printer Machine

-

Sublimation Fabric Printing Machine

-

Fedar Sublimation Printer

-

Skycolor Inkjet Printer

-

Storm Jet Printer

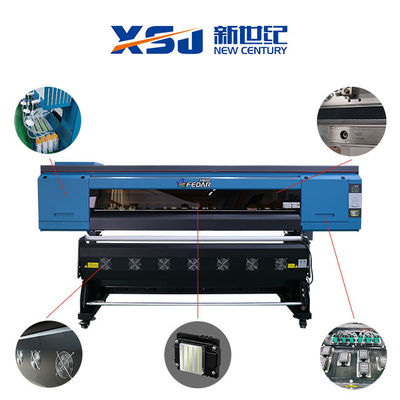

Fedar I3200 A1 4720 6 Heads Sublimation Textile Printer

| Usage | 45Gsm Transfer Paper | Head | I3200-A1 Or 4720 |

|---|---|---|---|

| Head Quantity | 6 | Media Loading | 2000m |

| Application | Sportswear, Dress, Curtain, Etc. | RIP Software | Neostampa, Photoprint |

| Print Width | 1.9m | Color | CMYK |

| Ink Type | Sublimation Ink, Water Based Pigment Ink | Warranty | 1 Year |

| Motor | Industrial Leadshine Motor | Guide Rail | THK Or Hiwin |

| High Light | 4720 6 Heads Sublimation Textile Printer,I3200 A1 Sublimation Textile Printer,Fedar I3200 A1 Sublimation Printer |

||

Original 4720 Head I3200 A1 Sublimation Textile Printer With 6 Heads from Fedar

Parameter for Sublimation Textile Printer

| Fedar FD1946 | ||||

| Printhead | Original Epson4720 | Nozzle Quantity | 3200 | |

| Printhead Quantity | 6(*8 is optical) | Print Width | 1900mm | |

| Ink Color | CMYK | Print Height | 2-5mm | |

| Resolution | 360*1200/360*1800/ 720*1200/720*1800(DPI) |

Media Transfer | Auto Media Feeding and Taking-up System, Roll to Roll |

|

| Speed *Tested on linear printing without feather function |

2pass | 200㎡/h | Drying Method | Extra Dryer Device |

| 4pass | 120㎡/h | Ink Supply Method | Siphon Positive Pressure Ink Supply | |

| 6pass | 60㎡/h | Head Moisture Method |

Auto Head Cleaning and Moisturize | |

| *speed is tested on full-size media without feather function |

Print Media | Transfer Paper | ||

| Ink Type | Sublimation Ink, Water based Pigment Ink |

Transmission Interface |

Gigabit LAN | |

| Computer System | Win7, Win8, Win10 | File Forms | TIFF, JPG, EPS, PDF, etc. | |

| Operate Environment | Temp.:15℃-30℃, Humidity: 35℃-65℃ | RIP Software | NeoStanpa,Ergosoft, Onyx,Photoprint,Maintop |

|

| Package Size | 3900*1340*1920mm | Power Supply | 210-230V, 50/60HZ, 16A Print Power: 1500W Dryer Power: Max.9000W |

|

| Computer Configuration | Hard Disk: NTFS, C Disk Space: More than 100G, HARD Disk:WG500G GPU: ATI Discrete GPU, CPU: Inte I5/I7, Gigabit LAN |

|||

| Standard Configuration | Ink Level Alarm System | |||

Original 4720 Head Introduction

Printing width of EPS4720 is 1.3 inch,about 30% wider than DX5 and 5113,printing speed can reach 200sqm/h with 2 pass,also with 3200 nozzles(800*4lines),it has much higher speed and resolution than Dx5 and 5113. EPS4720 printhead adopts TPF technology,with the smallest droplet 2.5PL,variable dots technology,can ensure perfect and high resolution printing performance. Also this head support smaller dot print model which can improve print resolution.

![]()

Features of FD1946

1. Servo Motor: LEADSHINE (Famous Brand in China)

2. Guide Line: HIWIN (Famous Brand in China) or THK (Famous Brand in Japan)

3. Cartridge: Original Import (Clean, Pump and Moisturize Automatically)

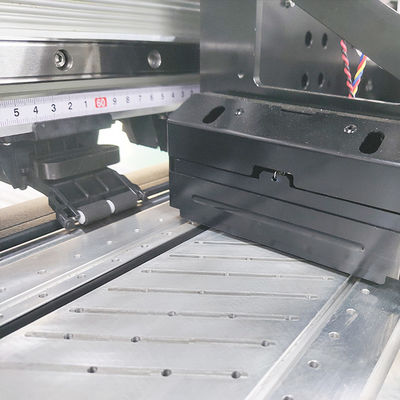

FD1946 Sublimation Textile Printer Detail Picture Show

![]()

![]()

Why Fedar Sublimation Textile Printer is Popular?

1. Ink supply system

Adopting a two-level ink supply system, which keeps printing for a long time to ensure the output quality of the picture

2. Software

Using international high-end software, the picture is more realistic and the reproducibility is better.

3. Brushless motor

Bi-directional Leisai brushless motor, high-precision drive linear decoding, higher accuracy, smaller length error, and more stable performance.

4. Intelligent ink shortage alarm

Intelligent ink shortage reminder, reducing the tediousness of frequently checking the ink remaining amount, and promptly reminding to add ink to ensure the continuity of printing work

5. Capping station

Equipped with advanced intelligent nozzle cleaning and moisturizing device, providing safe and convenient nozzle cleaning and maintenance functions, and more convenient operation and maintenance.

6. Japan THK guide

Adopt Japanese THK silent linear guide, the movement is more stable and the life is longer.

7. Press roller

American fluororubber press roller, prevent static electricity from flying ink, more accurate print size, reject wrinkles

Application

Sublimation Textile Printer application is widely, So far it mainly used in Sportswear, Dress, Curtain, Bags, Shoes, etc. This new type machine will replace traditional textile machine. Because it's print speed and print type is more and protect environment, then this machine will leading the textile market soon.

![]()