-

Sublimation Inkjet Printer

-

Sublimation Textile Printer

-

Large Format Eco Solvent Printer

-

Digital Inkjet Printing Machine

-

Digital Printing Plotter

-

UV Inkjet Printer

-

Transfer Paper Printing Machine

-

Epson Wide Format Inkjet Printer

-

Advertising Printing Machine

-

Commercial Poster Printer Machine

-

Sublimation Fabric Printing Machine

-

Fedar Sublimation Printer

-

Skycolor Inkjet Printer

-

Storm Jet Printer

CMYK 4 Heads I3200 A1 Polyester Printing Machine

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Head | I3200 A1 | Head Quantity | 4 |

|---|---|---|---|

| Print Width | 1900mm | RIP Software | Neostampa, Photoprint |

| Color | CMYK | Ink Type | Sublimation Ink |

| Media Loading | Tension System | Warranty | 1 Year |

| Material | Transfer Paper | Loading Media | 300m |

| Motor | Leadshine | Loading | 300m |

| Highlight | I3200 A1 Polyester Printing Machine,CMYK Polyester Printing Machine,CMYK 4 Heads Polyester Printer |

||

I3200 A1 Digital Printing Plotter In Textile Market For Polyester

![]()

Parameter for sublimation printer

| FD5194E Dye Sublimation Printer | ||||

| Printhead | Epson4720 | Nozzle Quantity | 3200 | |

| Printhead Quantity | 4 | Print Width | 1900mm | |

| Ink Color | CMYK | Print Height | 2-5mm | |

| Resolution | 360*1200/360*1800/ 720*1200/720*1800(DPI) |

Media Transfer | Auto Media Feeding and Taking-up System, Roll to Roll |

|

| Speed *Tested on linear printing without feather function |

2pass | 150㎡/h | Drying Method | Extra Dryer Device |

| 4pass | 110㎡/h | Ink Supply Method | Siphon Positive Pressure Ink Supply | |

| 6pass | 90㎡/h | Head Moisture Method |

Auto Head Cleaning and Moisturize | |

| *speed is tested on full-size media without feather function |

Print Media | Transfer Paper | ||

| Ink Type | Sublimation Ink, Water based Pigment Ink |

Transmission Interface |

Gigabit LAN | |

| Computer System | Win7, Win8, Win10 | File Forms | TIFF, JPG, EPS, PDF, etc. | |

| Operate Environment | Temp.:15℃-30℃, Humidity: 35℃-65℃ | RIP Software | NeoStanpa,Ergosoft, Onyx,Photoprint,Maintop |

|

| Package Size | 3458*1150*1780mm | Power Supply | 210-230V, 50/60HZ, 16A Print Power: 1500W Dryer Power: Max.7000W |

|

| Computer Configuration | Hard Disk: NTFS, C Disk Space: More than 100G, HARD Disk:WG500G GPU: ATI Discrete GPU, CPU: Inte I5/I7, Gigabit LAN |

|||

| Standard Configuration | Ink Level Alarm System | |||

Features

![]()

Advantages

1. The precision of printing table are controlled within ± 0.075mm. Make basical for high presison and quality printing during produce.

2. It can protect operator’s hand and avoid heads connect with papers, to pro-long heads service life--Anti collision system.

3. Independent R D double heads split & joint adjustment. Let heads vertical calibration is easy and convenient. Printing heads height can be adjust 2~10mm adopting different materials thickness---provide print resolution and eliminate pass banding.

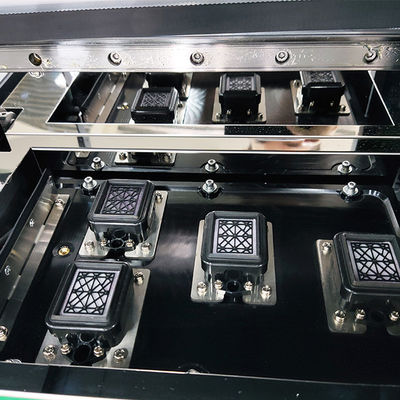

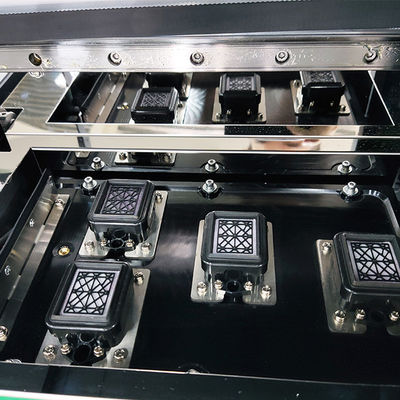

4. The capping station is imported from overseas to ensure its reliability and permanence. It can protect and clean head efficiently and conveniently. It can clean head, moisturize and pump ink Full automatically. Keep ink supply system work fluently---keep head moisture well.

5. Original import from Japan THK guide line can keep high precision, low noise and long time service life--- increase life time.

6. Both servo and step motor using brushless DC motor. High precision drive linearly decoded, lower deviation and run more stable.

7. We use high speed fiber to replace traditional data cables between main board and printing board. This will be faster and stable during printer working.

8. Keep inks supply height the same during printing and let heads have constant inkjet pressure. Can keep printers work more stable. 4pcs 3L huge, impendent ink tank and supply inks continuously.

9. VSDT variable dot technology can let heads choose different resolution for different quality photos achieve perfect printing.

10. Keep right and left have same pulling force can take up printing materials regularly.

Widely Applications

Sportswear

Cloth

Dress

Curtain

Shoes

Polyesters

Blue paper

![]()