-

Sublimation Inkjet Printer

-

Sublimation Textile Printer

-

Large Format Eco Solvent Printer

-

Digital Inkjet Printing Machine

-

Digital Printing Plotter

-

UV Inkjet Printer

-

Transfer Paper Printing Machine

-

Epson Wide Format Inkjet Printer

-

Advertising Printing Machine

-

Commercial Poster Printer Machine

-

Sublimation Fabric Printing Machine

-

Fedar Sublimation Printer

-

Skycolor Inkjet Printer

-

Storm Jet Printer

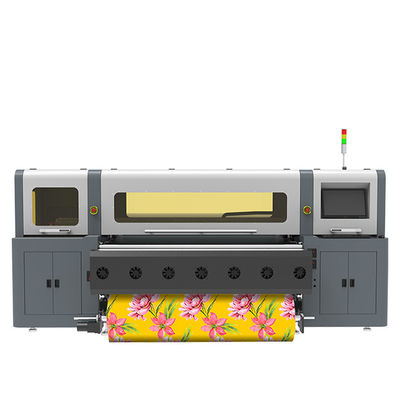

CMYK 1.8m Cotton Belt Fedar Sublimation Printer 3200dpi

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Printhead Type | Epson I3200-A1 | Quantity | 6/8 Pcs |

|---|---|---|---|

| Ink Color | CMYK | Ink Type | Pigment,Disperse,Reactive,Acid Ink. |

| Printing Width | 1800mm | Computer System | WIN7 64bit/WIN10 64bit |

| Media | Cotton, Flax, Ployester, Silk, Etc. | RIP Software | Maintop, Print Factory, NeoStampa(optional) |

| Warranty | 1 Year | Resolution | 3200dpi |

| Highlight | Cotton Belt Fedar Sublimation Printer,CMYK 1.8m Fedar Sublimation Printer,3200dpi Fedar Sublimation Printer |

||

FEDAR 1.8m Cotton Belt Direct Prinrt Printer Using EpsOn I3200-A1 Heads

Technical Parameters

| TECHNICAL PARAMETERS | |||||

| Printhead | EPSON I3200-A1 | Resolution | 3200DPI | ||

| Printhead Quantity | 6/8 | Ink Color | CMYK | ||

| Print Media | Cotton, Flax, Ployester, Silk, etc. | Ink Type | Pigment / Disperse / Reactive / Acid Ink | ||

| Printing Width | 1800mm | RIP Software | Maintop, Print Factory, neoStampa(optional) | ||

| Speed *Tested on linear printing without feather function |

2 Pass | 6 Heads | 160㎡/h | 8 Heads | 230㎡/h |

| 4 Pass | 92㎡/h | 140㎡/h | |||

| 6 Pass | 60㎡/h | 85㎡/h | |||

| Ink Supply Method | Negative Pressure Ink Supply | Media Transmission | Auto Take-up Media System, Damping Feeding Media System | ||

| Heating System | Extra Independent Dryer | Head Clean | Auto-clean, Auto-flash Moisturize | ||

| Image Format | BMP,TIFF, JPG, EPS, PDF, etc. | Operate Environment | Temp.:15℃-30℃, Humidity: 45%-70% |

||

| Machine Size/Weight | 3400*2100*1500mm 1500KG |

Power Supply | AC220V, 50/60HZ, 9000W | ||

Details

![]()

![]()

1.This FD1882 cotton printer support 4 colors print or 8 colors print, intelligent capping station design

which is more easy to do calibrate.

2.Import quality belt, more longer lifetime.

![]()

![]()

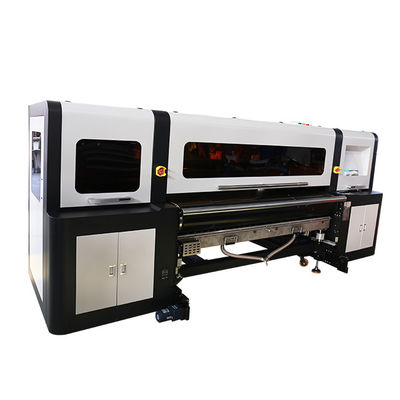

3.Smart feeding media system, used for more tension materials or others.

4.Using double import THK guide rail, let carriage move more smoothly and reduce noice.

![]()

![]()

5.Big ink tank design with alarm warning system, reduce fill ink times.

6.Three-color alarm is convenient for operators to add ink in time.

Application

![]()

![]()