-

Sublimation Inkjet Printer

-

Sublimation Textile Printer

-

Large Format Eco Solvent Printer

-

Digital Inkjet Printing Machine

-

Digital Printing Plotter

-

UV Inkjet Printer

-

Transfer Paper Printing Machine

-

Epson Wide Format Inkjet Printer

-

Advertising Printing Machine

-

Commercial Poster Printer Machine

-

Sublimation Fabric Printing Machine

-

Fedar Sublimation Printer

-

Skycolor Inkjet Printer

-

Storm Jet Printer

3 Or 4 Heads CMYK Epson Heat Transfer Printer 150m2/H

| Head | 4720 | Head Quantity | 4 |

|---|---|---|---|

| Print Width | 1900mm | RIP Software | Neostampa |

| Color | CMYK | Ink | Sublimation Ink |

| Taking-up System | Tension System | Warranty | 1 Year |

| Material | Transfer Paper | Loading Media | 300m |

| High Light | CMYK Epson Heat Transfer Printer,Epson Heat Transfer Printer 150m2/H,4 Heads 1.9m Heat Transfer Printer |

||

Fedar Sublimation Printer 3 or 4 Heads Economic Model

Parameter

| FD5194E Dye Sublimation Printer | ||||

| Printhead | Epson4720 | Nozzle Quantity | 3200 | |

| Printhead Quantity | 4 | Print Width | 1900mm | |

| Ink Color | CMYK | Print Height | 2-5mm | |

| Resolution | 360*1200/360*1800/ 720*1200/720*1800(DPI) |

Media Transfer | Auto Media Feeding and Taking-up System, Roll to Roll |

|

| Speed *Tested on linear printing without feather function |

2pass | 150㎡/h | Drying Method | Extra Dryer Device |

| 4pass | 110㎡/h | Ink Supply Method | Siphon Positive Pressure Ink Supply | |

| 6pass | 90㎡/h | Head Moisture Method |

Auto Head Cleaning and Moisturize | |

| *speed is tested on full-size media without feather function |

Print Media | Transfer Paper | ||

| Ink Type | Sublimation Ink, Water based Pigment Ink |

Transmission Interface |

Gigabit LAN | |

| Computer System | Win7, Win8, Win10 | File Forms | TIFF, JPG, EPS, PDF, etc. | |

| Operate Environment | Temp.:15℃-30℃, Humidity: 35℃-65℃ | RIP Software | NeoStanpa,Ergosoft, Onyx,Photoprint,Maintop |

|

| Package Size | 3458*1150*1780mm | Power Supply | 210-230V, 50/60HZ, 16A Print Power: 1500W Dryer Power: Max.7000W |

|

| Computer Configuration | Hard Disk: NTFS, C Disk Space: More than 100G, HARD Disk:WG500G GPU: ATI Discrete GPU, CPU: Inte I5/I7, Gigabit LAN |

|||

| Standard Configuration | Ink Level Alarm System | |||

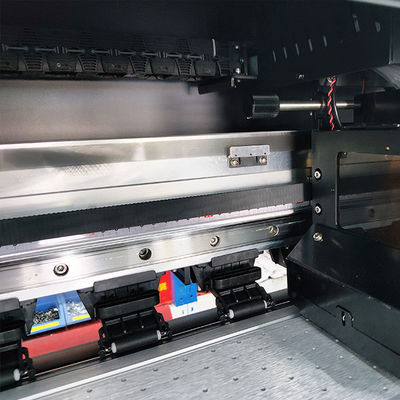

Features Detail Shows

![]()

![]()

Features:

Servo Motor: LEADSHINE (Famous Brand in China)

Guide Line: HIWIN (Famous Brand in China) or THK (Famous Brand in Japan)

Cartridge: Original Import (Clean, Pump and Moisturize Automatically)

Main Board: Design and Produced by ourselves, it is stability and 12Months Warranty time

Ink Supply System: Bulk Ink Continues Supply System

Advantages

1. High Precision Printing Table

The precision of printing table are controlled within ± 0.075mm. Make basical for high presison and quality printing.

2. Hand Safety Sensor on Carriage

It can protect operator’s hand and avoid heads connect with papers, to pro-long heads service life.

3. Adjustable Printing Carriage

Independent R D double heads split & joint adjustment. Let heads vertical calibration is easy and convenient. Printing heads height can be adjust 2~10mm adopting different materials thickness.

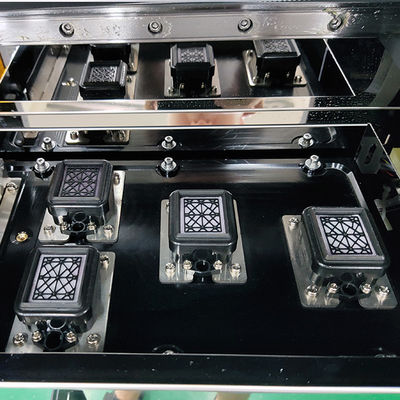

4. Automatic Cartridge Capping Station

The capping station is imported from overseas to ensure its reliability and permanence. It can protect and clean head efficiently and conveniently. It can clean head, moisturize and pump ink Full automatically. Keep ink supply system work fluently.

5. Japan THK Taiwan Hiwin & Original Guide Line

Original import from Japan THK guide line can keep high precision, low noise and long time service life.

6. Servo and Step Motor

Both servo and step motor using brushless DC motor. High precision drive linearly decoded, lower deviation and run more stable.

7. High Speed Fiber

We use high speed fiber to replace traditional data cables between main board and printing board. This will be faster and stable during printer working.

8. Constant Pressure Two Level Ink Supply System and Ink Tank

Keep inks supply height the same during printing and let heads have constant inkjet pressure. Can keep printers work more stable. 4pcs 1.5L huge, impendent ink tank and supply inks continuously.

9. Original research two dimension intelligent and wave eclosion function can avoid BANDING during printing to increase printing quality.

10. VSDT Variable Dot Technology

VSDT variable dot technology can let heads choose different resolution for different quality photos achieve perfect printing.

11. Double Motor Materials Taking Up Roller

Keep right and left have same pulling force can take up printing materials regularly.

12. Infrared + Dry Fans

Independent R D infrared and drying fans can dry printing materials in short time.

Widely Application

![]()

![]()