-

Sublimation Inkjet Printer

-

Sublimation Textile Printer

-

Large Format Eco Solvent Printer

-

Digital Inkjet Printing Machine

-

Digital Printing Plotter

-

UV Inkjet Printer

-

Transfer Paper Printing Machine

-

Epson Wide Format Inkjet Printer

-

Advertising Printing Machine

-

Commercial Poster Printer Machine

-

Sublimation Fabric Printing Machine

-

Fedar Sublimation Printer

-

Skycolor Inkjet Printer

-

Storm Jet Printer

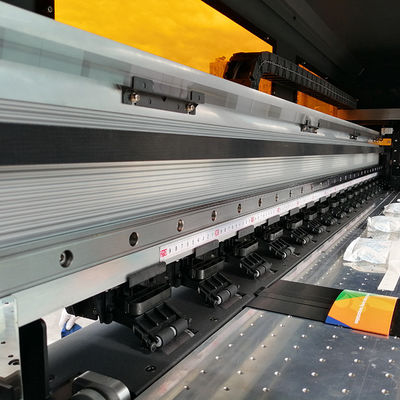

1.9m I3200 Heads Dye Sublimation Printing Machine Textile Flex Polyester Nylon

| Printhead | EPS I3200-A1/E1/DX5 | Printing Speed | 150sqm/h |

|---|---|---|---|

| Ink Type | Sublimation Ink, Pigment Ink,water Based Ink | RIP Software | Maintop,Photoprint,Neostampa,Onyx,etc |

| Print Width | 1900mm | Print Height | 2-5mm |

| High Light | I3200 Heads Dye Sublimation Printing Machine,1.9m Dye Sublimation Printing Machine,1.9m I3200 fabric sublimation printer |

||

1.9m I3200 Heads Digital Textile Flex Polyester Nylon Fabric Dye Sublimation Printing Machine

Our sublimation printer is used to make textile products, such as blanket, polyester dress, plush toys and so

on. It prints on sublimation papers first, then heat transfer the pattern to the fabric you want. Automatic

printing and dye sublimation ink make the pattern colors bright, strong and fantastic.

Digital Textile Flex Polyester Nylon Fabric Dye Sublimation Printing Machine Parameters

FEDAR 1.9m Water Transfer Sublimation Fabric Printing Machine Feature

1. At the same time, it is equipped with four Epson industrial grade nozzles, with 3200 spray holes. The printing speed of

4pass can reach 90 square / h, and the maximum speed is 150 square / h; TFP thin film piezoelectric technology, printing comprehensive upgrade; 2.5pl variable point, showing fine printing quality; Speed and quality are improved simultaneously.

2. Air expansion shaft type retracting and releasing system: during operation, it does not need to fix the printing medium with the help of other accessories, and uses the air pressure to adjust automatically. Make the force uniform, make the paper more smooth. The system has the characteristics of large load, long service life, uniform force on paper placing and receiving, and short operation time of inflation and deflation.

3. The stable flying butterfly independent printing system and its core components are all made of high-quality accessories in the industry, such as Japanese THK ultra quiet linear guide rail, Japanese NSK bearing, German igus tank chain, leisai brushless integrated motor, which ensure the accuracy of the machine and the stability of long-time work.

4.Adopt a new integrated cleaning and moisturizing ink stack module.

5.Staggered arrangement of trolley bottom plate, convenient adjustment and higher precision.

6.Multiple Epson nozzles, speed up to 150 sqm/h.

7.Gigabit network data transmission port to meet the requirements of digital printing high-definition picture output stability and transmission speed

8.Imported accessories: THK ultra-quiet guide rail, Japanese NSK bearing, German igus ink chain, Leisai integrated servo motor.

9.Automatic tension retractor, fast storage of printing media, automatic paper measurement, anti-scratch paper curling, protection of the print head.

Wide Format Printer Sublimation Detail

Printing Process

FD6194E Printing Machine Wide Application

Sublimation transfer is widely used on digital polyester printing, which is vivid on color, no need make plate,no waste

generated, no quantity request, even small quantity of order or customized order can be processed.

![]()